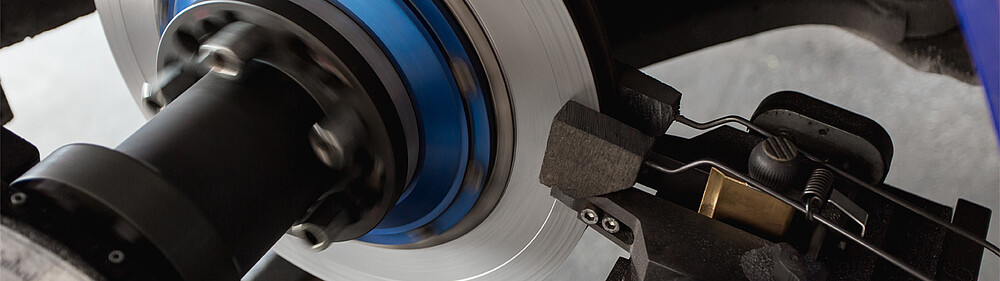

Reliable measurement of wear protection on brake discs

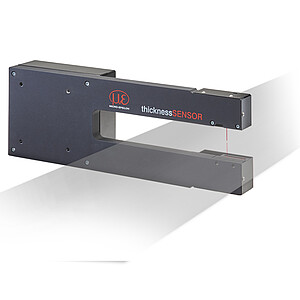

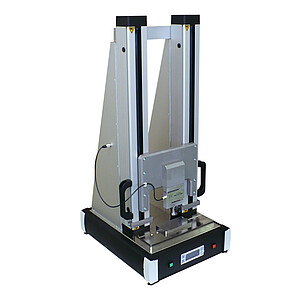

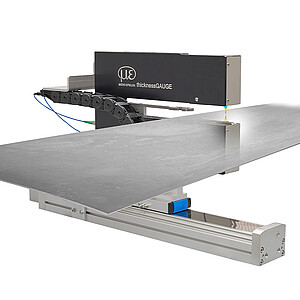

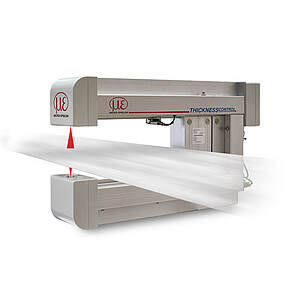

The new EURO 7 emissions standard, which includes standards for brake and tire abrasion for the first time, will apply to new vehicle registrations from the fourth quarter of 2026. In order to comply with the limit values, new brake discs are given a protective coating of tungsten or titanium carbide. Each layer applied is usually 100 to 200 µm thick. To determine the thickness of the individual layers, the distance to the surface is measured before and after each application. The distance values are then calculated either in the associated controller or in an evaluation unit provided by the customer to determine the coating thickness.

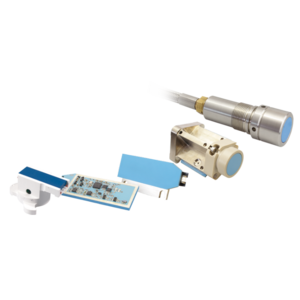

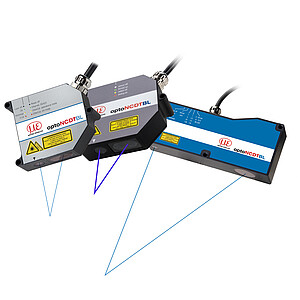

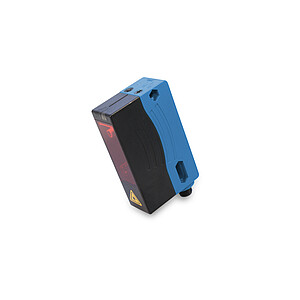

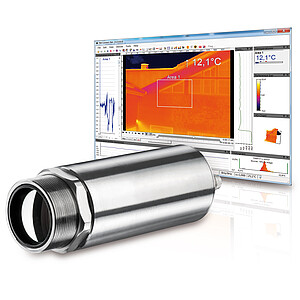

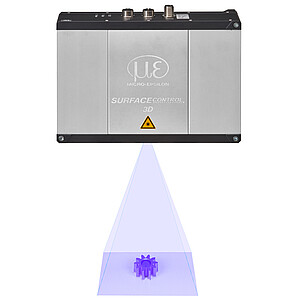

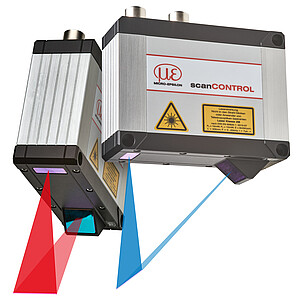

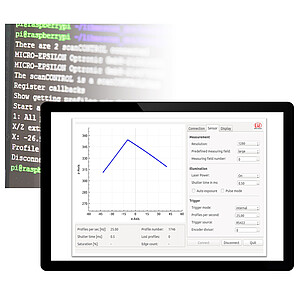

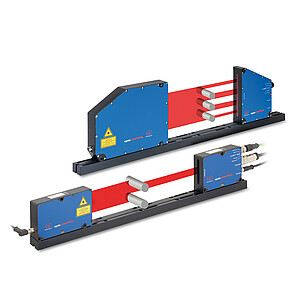

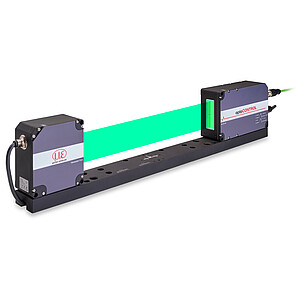

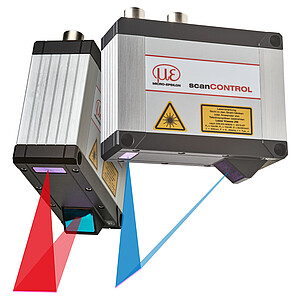

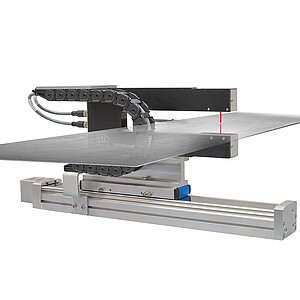

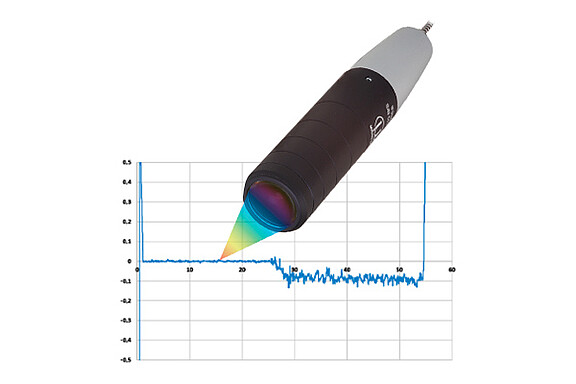

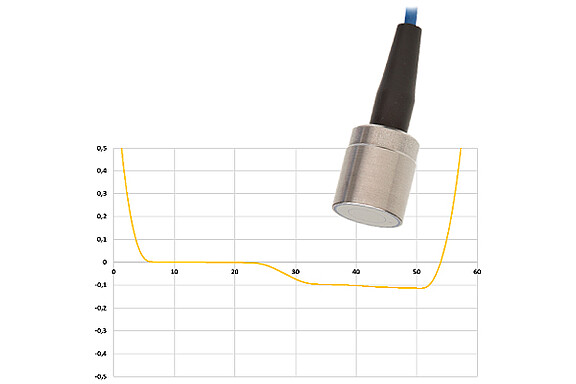

Depending on the requirements, confocal chromatic, capacitive or laser-optical sensors from Micro-Epsilon are used. Regardless of the measuring principle, each of the sensors mentioned achieves the required accuracies of less than 20 µm and offers different advantages for reliably measuring the rough surface in powder-loaded environments and at high temperatures.